UHMWPE HMPE HPPE Dyneema Bulletproof Ballistic Cooling Staple Fiber 10D/20D/30D/50D/75D/100D/200D/350D/400D/1000D UD Fabric Sheet

Main Properties

◎ Lower density than water

◎ Extremely high ratio of weight-strength and weight-modulus

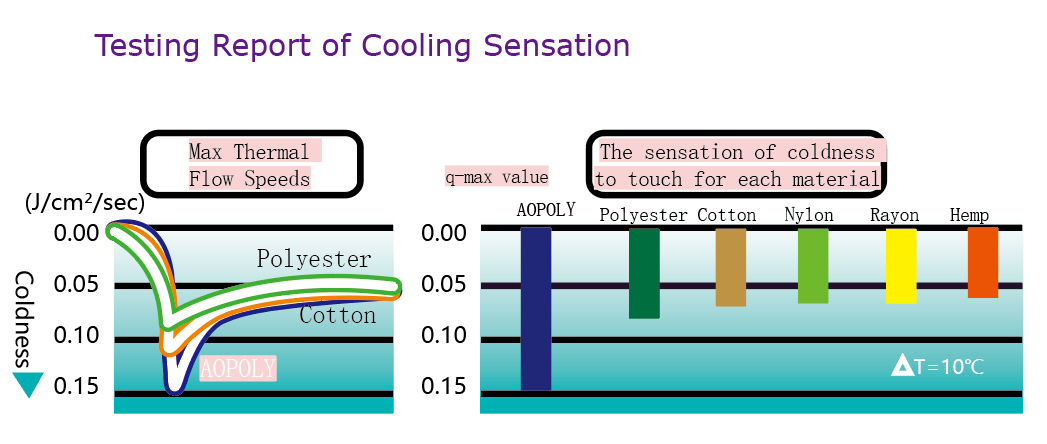

◎ At least double cooling sensation of other raw materials

◎ Excellent resistance with salty, acid, alkali and other most chemicals

◎ Resistant to stretching and bending fatigue, features a long flexibility lifetime

◎ Low elongation ratio at break, high breaking strength, outstanding cut resistance

◎ Good UV, neutron and γ-ray resistance, low dielectric constant, high electromagnetic wave transmittance

◎ Excellent impact resistance, high impact absorption capacity that is nearly 2 times greater than aramid, high abrasion resistance and low friction coefficient

Main Applications

Bulletproof Armor: bulletproof armor, ballistic helmet, bomb suppression blanket, ballistic plate, etc.

Oceaneering: drilling platform, anchor cable, towrope, mooring rope, terminal hoisting rope, etc.

Industrial Applications: cut-resistant gloves, hoisting rope, wind power cable, etc.

Aerospace Engineering: aircraft wing tip component, spacecraft component, buoy of aircraft, aviation cage, spacecraft component, etc.

Marine Fisheries: commercial fishing net, marine aquaculture net, salvage rope, towing rope, sailing rope, etc.

Outdoor Sports: climbing rope, parachute rope, sailing rope, kite line, fishing line, helmet, sail round plate, ultra-low-weight aircraft parts, etc.

Biological Material: denture base material, graft and plastic sutures, etc.

Industrial fields: pressure container, conveyor belt, filtration material, automobile cushion plate, etc.

Construction: wall, diaphragm structure, reinforced cement composite material, etc.

Parameters

Performance comparison between UHMWPE / HMPE fiber and other fibers

| Fiber Type | Steel fiber | Glass fiber | Carbon fiber | Aramid Fiber | UHMWPE fiber |

| Density (g/cm3) | 7.8 | 2.6 | 1.97 | 1.45 | 0.97 |

| Melting Point (oC) | 1150~1500 | 500~2000 | 500~560 | 135~145 | |

| Elongation (%) | 1.1-1.4 | 4.8 | 0.5~2 | 2.4~4.4 | 3.5~3.7 |

| Modulus (Gpa) | 50 | 72 | 230~400 | 60~120 | 70~132 |

| Strength (g/d) | 2.5~2.8 | 15 | 22~30 | 22~26 | 32~40 |

Specification of UHMWPE Filament Yarn

| Item No | Linear density | Tensil strength | Modulus | Elongation at break | |

| (Denier) | (dtex) | (cN/dtex) | (cN/dtex) | (%) | |

| AP-HMP-10 | 10D | 11 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-15 | 15D | 17 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-20 | 20D | 22 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-25 | 25D | 28 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-30 | 30D | 33 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-40 | 40D | 44 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-50 | 50D | 55 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-75 | 75D | 83 | ≥38 | ≥1400 | ≤3.5 |

| AP-HMP-100 | 100D | 111 | ≥35 | ≥1350 | ≤3.0 |

| AP-HMP-125 | 125D | 139 | ≥35 | ≥1350 | ≤3.0 |

| AP-HMP-150 | 150D | 165 | ≥34 | ≥1300 | ≤3.0 |

| AP-HMP-175 | 175D | 193 | ≥33 | ≥1250 | ≤3.0 |

| AP-HMP-200 | 200D | 222 | ≥33 | ≥1250 | ≤3.0 |

| AP-HMP-225 | 225D | 248 | ≥33 | ≥1250 | ≤3.0 |

| AP-HMP-250 | 250D | 275 | ≥33 | ≥1250 | ≤3.0 |

| AP-HMP-300 | 300D | 333 | ≥32 | ≥1200 | ≤3.0 |

| AP-HMP-350 | 350D | 389 | ≥32 | ≥1200 | ≤3.0 |

| AP-HMP-400 | 400D | 444 | ≥32 | ≥1200 | ≤3.0 |

| AP-HMP-500 | 500D | 555 | ≥32 | ≥1200 | ≤3.0 |

| AP-HMP-600 | 600D | 667 | ≥32 | ≥1200 | ≤3.0 |

| AP-HMP-700 | 700D | 777 | ≥30 | ≥1100 | ≤3.5 |

| AP-HMP-800 | 800D | 889 | ≥34 | ≥1200 | ≤3.5 |

| AP-HMP-1200 | 1200D | 1333 | ≥34 | ≥1200 | ≤3.5 |

| AP-HMP-1600 | 1600D | 1778 | ≥34 | ≥1200 | ≤3.5 |

More UHMWPE / HMPE fiber Products

| Type | Size | Advantage | Application |

| Staple | 1.21dtex*38mm 1.21dtex*51mm 1.91dtex*38mm 1.91dtex*51mm |

Soft hand-feel, Good spinnability | Cool fabric, Apparel fabric, High strength sewing thread and industry fabric |

| Nets | Mesh Depth: Max 1000D | High strength with lower weight | Fishery, Farm fishing acquaculture net |

| Covered Yarn | With glass fiber, Steel wire, | Soft hand-feel, Cutting resistance | Cutting resistance gloves, Sports fabric |

| Spinning Yarn | With glass fiber, Steel wire | Soft hand-feel, Anti-cut, Anti-stab | Composite materials |

| UD Fabric | I, IIA, II, IIIA, III, IV | Soft texture, Good protective performance | Labor and armor protection |

| Woven & Knitted Fabric | Produced by customization | High strength, Cool feeling, Anti-cut, Anti-stab, Abrasion resistance | Sports, Industry, Hometextile |